Category Archives: Latest Posts

People and places: Chrys Meader’s history of Marrickville by Sue Castrique

People and places: Chrys Meader’s history of Marrickville

By Sue Castrique ©

It took several readings before I came to understand the significance of the cover of Marrickville: Rural Outpost to Inner City. The photograph shows Marrickville Town Hall being opened in 1922. On first glance the photo perfectly captures the book’s subject, but while the new town hall is imposing, within the ring of bunting and onlookers stands Winged Victory, her pedestal wreathed in garlands, her sword lifted to the air. This was the statue Chrys Meader tried so hard to save.

Chrys Meader and Richard Cashman wrote Marrickville: Rural Outpost to Inner City in 1990. Its companion Marrickville: People and Places was published four years later in 1994 with a third writer, Anne Carolan. Originally conceived as a single volume, they were split into two to make it easy for publication and readers. They have been essential local histories ever since.[1]

In significant ways Marrickville Council housed, defined and nurtured this history. Richard Cashman was a Marrickville councillor from 1980 to 1982 and Chry Meader a council librarian. They drew on an archive created over decades by Frances Charteris, the Chief Librarian at Marrickville Council from 1955. Frances had a keen historical consciousness and created the Local Studies Collection with community donations, records and photographs and the Archives Reference Collection from original council documents. Chrys continued to care for and add to the collections, retrieving valuable council documents from storage rooms, lofts and the ‘rat poison room’. Here was a gold mine of material bursting with all the small necessary details that are the backbone of historical research.[2]

There were not just printed documents. The library was a community hub for people and stories. As Diane McCarthy remembers, people dropped into the library to borrow books, but then stayed to talk, sharing memories and telling stories about where they lived and how they came to be here. This was a local history created from local archives and memory.[3]

Marrickville was defined in Cashman and Meader history by its political boundaries. They set their work within the local council of Marrickville which by 1990 had merged with the councils of Camperdown, Newtown, St Peters and Petersham, creating a sprawling local government area that stretched from Cooks River to Annandale.

St Peters Town Hall

St Peters Town Hall is an Australian heritage listed town hall located at 39 Unwins Bridge Road, Sydenham. Built in 1927. St Peters Council operated from 1871 -1949 before it was amalgamated with Marrickville Council and now Inner West Council. when St peters was proclaimed a municipal district on 13 January 1871 it covered 2 square miles(5.2 sq km ) and had a population of just 500 people. Today in 2021 St Peters/ Tempe has a population of 7846.

St Peters was an industrial suburb, in 1890 there were a total of 18 dairies as well as 2 brickmaking establishments. The dairies and the brickmakers vied for space. In the end brickmaking became the major industry of the area as the suburb developed.

An interesting fact was the construction of many tall chimneys, built to reduce air pollution.

2021 Heritage Festival Exhibition Marrickville Eikons May 1-30

Marrickville Eikons

Exhibition description

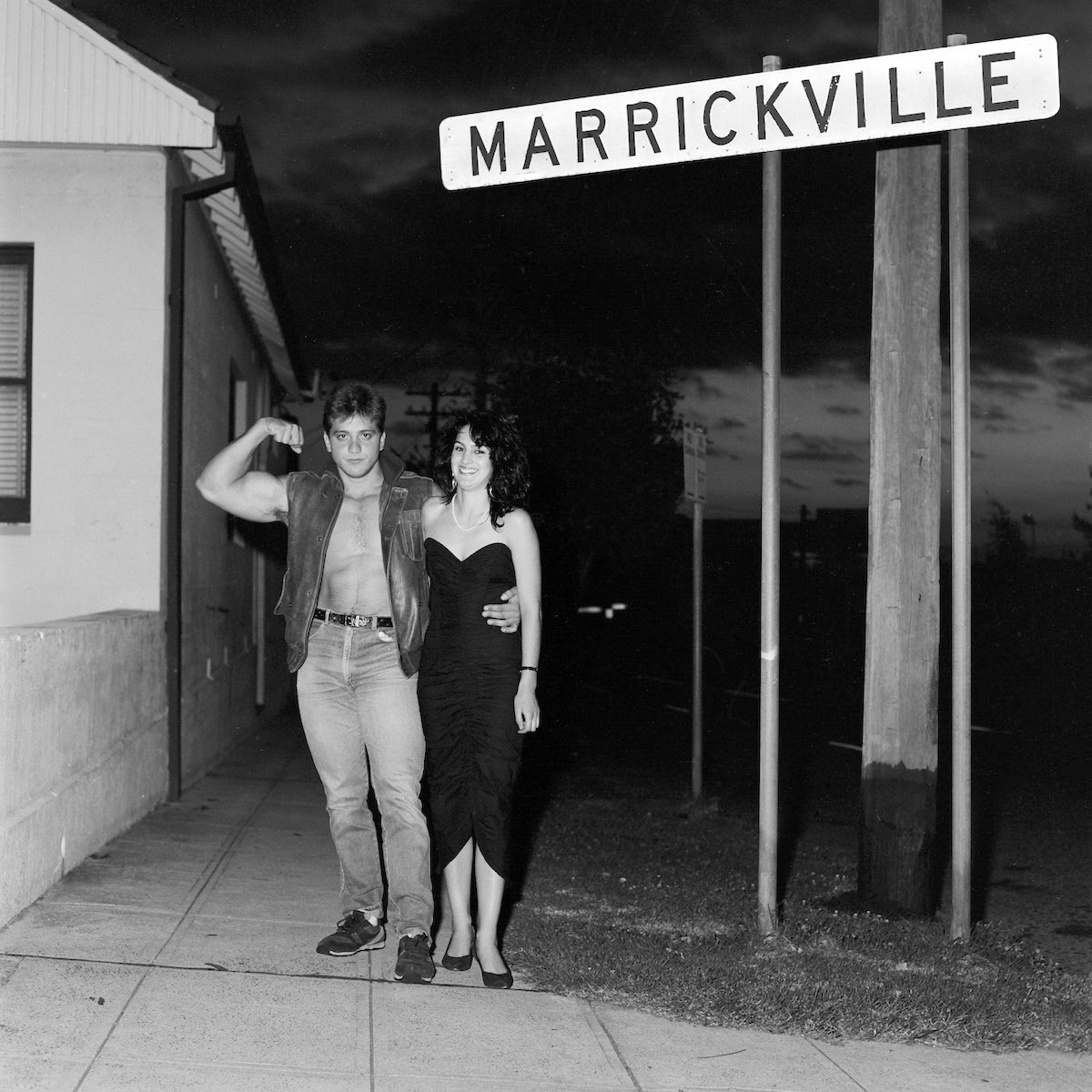

As part of the Australian Heritage Festival 2021, Marrickville Library is pleased to present iconic photographs of the Greek community in Marrickville, taken by Emmanuel Angelicas. Raised in the suburb, long term resident Emmanuel Angelicas has taken photographs for five decades, chronicling the changing face of Marrickville and its citizens.

These stunning monochromatic images are just a taste of the photographer’s archive and show aspects of the Hellenic influence. By the middle of the twentieth century, Marrickville was a major centre for Greek immigrants, often referred to as ‘Little Athens’. Over time, shops and businesses with a strong Greek identity became accepted as part of the wider Australian community and enriched our municipality. Through these images, older residents will smile with recognition and younger ones can connect with our recent history.

Artist bio

For fifty years, photographer Emmanuel Angelicas has roamed the streets of Marrickville, recording his neighbourhood in startling black and white images. His archive of negatives and digital images is huge and this exhibition showcases just a few of his iconic images of the Greek diaspora and their influence on our suburb. Marrickville’s complex identity owes much to the arrival of Hellenic migrants in the 1950s and 1960s and this is recognised today with the area’s affectionate title of Little Greece. Emmanuel Angelicas’s photographs span the generations with poignant images of those early arrivals and their descendants.

As he grew up in Marrickville, he became serious about the medium. He bought better cameras and graduated from the University of NSW with a degree in Visual Communication and postgraduate diploma in Professional Art Studies with further visual arts qualifications from the University of Sydney. The technology of photography has changed, but Emmanuel continues to record in black and white and is happy to use both film and digital cameras. His attitude to photography has never wavered either. “Every time I shoot in Marrickville, either in my home or on the street – I am still this seven-year-old boy curious with his camera…”

Olympia Milk Bar

The Olympia Milk Bar opened in 1939, following the closure of a billiard toom which had originally occupied the building. (Next door heading west along Parramatta Road) was the Olympia De-Luxe Picture Thetare which opened in 1911.

Both the cinema and milkbar did a roaring trade until the very early 1960s. Like many of the 50 cinemas in the Inner West were met with the advent of the television.

The Olympia cinema was then converted into a skating rink. During this era a growing youth culture patroned the milk bar, however by the mid 1970s a number if take away fast food outlets popped up and the teenage patrons declined in number.

It is really quite amazing that the the Olympia milk bar has survived so long up until the last 5 years the milk bar had retained much of its original character and the minds of many locals was on one of Parramatta Roads icons. Often a stop on the annual heritage festival walking tours of Annandale, frequented also by social historians, public history students, journalist, filmmakers and busgazers it has long been the cafe to spot and visit if you may and dive into the realms of nostalgia or experience what once was.

Most of the memories are held strongly in the minds of locals from the 50s, 60s and 70, Parrmatta Road was often referred to as lovers lane or the dating game as it was a tradition when going on a date to meet and the south end of Parrmatta road and chat and hold hands the length of the road the Olympia milk bar according to Stella Phillips was one of the places they would stop and buy a milkshake.

The current fate of the Olympia Milk Bar has certainly become of concern and a topic of discussion as the longtime occupier and owner Mr Nick Fotiou has moved into a nursing home.

We invite you to share your stories, memories and photos of the Olympia Milk Bar.

useful links for further social media.

Exhibition: Silent agreement Marrickville 50 Home

Come and check out this exhibition asap!

EMMANUEL ANGELICAS

ATLAS Community & Cultural Centre

96 Illawarra Rd

Marrickville NSW 2204

Australia

Festival Year: 14 November 2020 to 29 November 2020

Emmanuel Angelicas always wanted to be a photographer and on his

seventh birthday, his father humoured him with a plastic Diana camera. It took

just twelve images on roll film, but Emmanuel took to photography with

gusto… and soon ran out of film. Undaunted, he continued to press the

shutter, taking images in his mind. His childhood friends never knew whether

they were being immortalised or not.

As he grew up in Marrickville, he became serious about the medium. He

bought better cameras and graduated from the University of NSW with a

degree in Visual Communication and postgraduate diploma in Professional

Art Studies with further visual arts qualifications from the University of

Sydney.

BALMAIN CATHOLIC CEMETERY: Leichhardt’s best kept secret

BALMAIN CATHOLIC CEMETERY Leichhardt’s best kept secret

Balmain Catholic cemetery was located on 4 acres that now houses St. Columba’s church and presbytery, a primary school, associated buildings and a child care centre, originally built as a convent for the Sisters of St. Joseph, who taught at the school. The cemetery opened in 1868 and closed in 1902 and was progressively built over. There is no physical evidence that a cemetery ever existed there.

The story of the cemetery begins with the arrival of two men in 1818 at different times and on different ships, one of those was a young man who had studied law in England, had qualified as a solicitor and who came to New South Wales to make his fortune, he quickly  opened a legal practice in Sydney, became very successful, eventually becoming a member of the NSW Legislative Assembly, His name was James Norton. In 1834 Norton bought a large gentleman’s estate, known as the Eastwick Estate and which included a large house, befitting for a wealthy gentleman known as Eastwick House. The estate was roughly bounded by Parramatta Rd, Balmain Rd. Derbyshire St. William St. and Flood St. back to Parramatta Road.

opened a legal practice in Sydney, became very successful, eventually becoming a member of the NSW Legislative Assembly, His name was James Norton. In 1834 Norton bought a large gentleman’s estate, known as the Eastwick Estate and which included a large house, befitting for a wealthy gentleman known as Eastwick House. The estate was roughly bounded by Parramatta Rd, Balmain Rd. Derbyshire St. William St. and Flood St. back to Parramatta Road.

Coughing Again

“From a business point of view, Sydney is dead. Theatres, hotels, picture shows, eateries, schools etc. are closed. Sydney is a city of masks.”

Not a description of May 2020 but of February 1919 according to a newspaper article.

In this talk, renowned local historian Chrys Meader compares Sydney life during the 1919 Spanish flu pandemic to today’s Covid-19 pandemic.

Chrys’ knowledge of the Pneumonic Influenza (Spanish Flu) and it’s impact on the Inner West makes is unparalleled and makes for a fascinating talk.

Mirror Sydney – The Podcast

Missing your regular history talks and walks, why not tune in to these great podcasts created by local history blogger Vanessa Berry.

The newly-launched Mirror Sydney Podcast is based on the award-winning book and blog Mirror Sydney, by Vanessa Berry, with production and music by Lia Tsamaglou. Each episode delves into a familiar, enigmatic, or atmospheric place in the city or suburbs. Inner west residents will recognise a number of familiar locations in the first series!Berry’s investigations usually start at a point of idle fascination: a notorious op shop at the edge of the airport, Sydney’s least peaceful footpath, newly redundant train routes. What then unfolds is a vivid evocation of urban space, not just its streets, people and infrastructure, but the otherwise inaccessible ambience of its former life.Listen at https://mirrorsydneypodcast.com/ and you can also subscribe through your favourite podcast app.

Telling Your Story – Inner West COVID-19

History Collection Drive.

Council’s Library and History Services is collating a COVID-19 community archive and is seeking stories, anecdotes, artworks and images from Inner West citizens.

Right now, the community is experiencing an extraordinary occurrence. Contemporary accounts by everyday people will help future historians make sense of this major life event.

The archive will act as a ‘snapshot’ of the Inner West in lockdown – what it was like, how our world changed and how people were affected.

The community archive wants to hear from singles, families, young people, businesses and artists about how you have managed this time.

https://yoursay.innerwest.nsw.gov.au/telling-your-stories-inner-west-covid-19